Sensor class | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

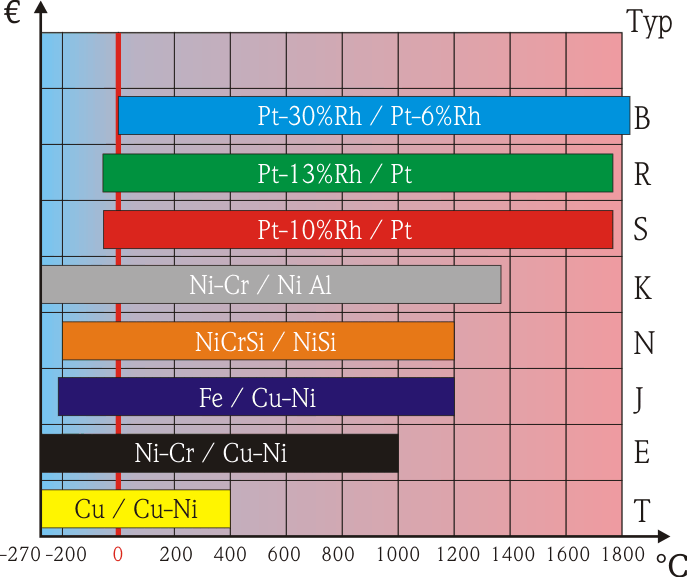

Dependent on the process temperature different thermocouples are applied.

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Dependent on the process temperature different types of thermodouples (e.g. normally K or J) are applied. The thermocouple can be found in the measurement insert. The measurement accuracy is dependent on a number of different factors:

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Thermocouple type: According to the DIN EN 60584 these are divided into precious and non-precious thermocouples. Non-precious thermocouples such as E, J, K, N and T are more economical and used for temperatures up to 1100 °C. Precious thermocouples such as B, R and S are costlier and suitable for temperatures up to 1820 °C.

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

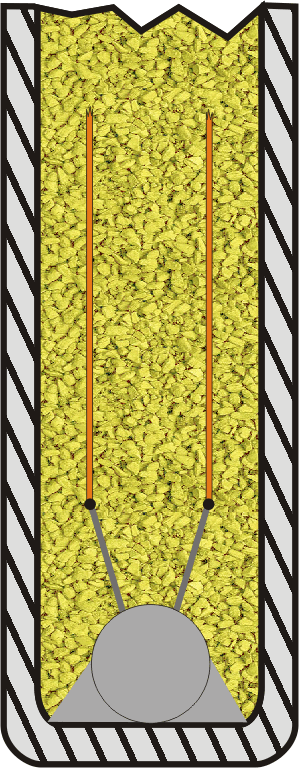

| Grounded

measurement points using sheathed thermocouples |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Features

The thermocouple is pressed into a highly compressed ceramic mass (magnesiumoxide powder MgO). Advantages: |

| ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

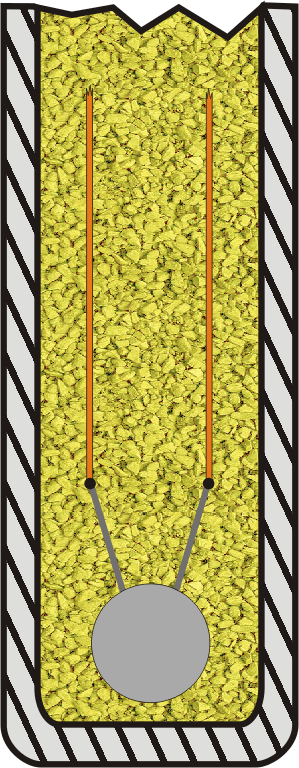

Non-grounded measurement

points using sheathed thermocouples |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Features:

The thermocouple is pressed into a highly compressed ceramic mass (magnesiumoxide powder MgO). Advantages: |

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Non-grounded measurement

point with ceramic insulationfor high temperature thermocouples |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Due to the ceramic insulation the thermo legs and the measurement point are protected and insulated from each other. This means that the stability of the measurement insert can be guaranteed. |

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Accuracy classifications: |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Measurement accuracy of a sensor: | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

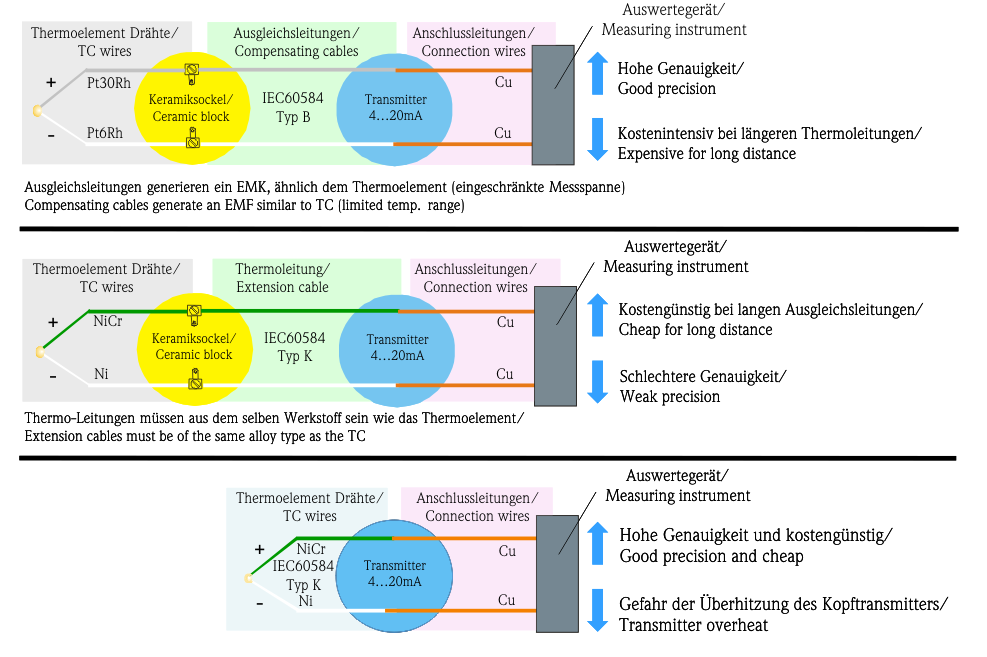

Thermocable, compensation cable |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

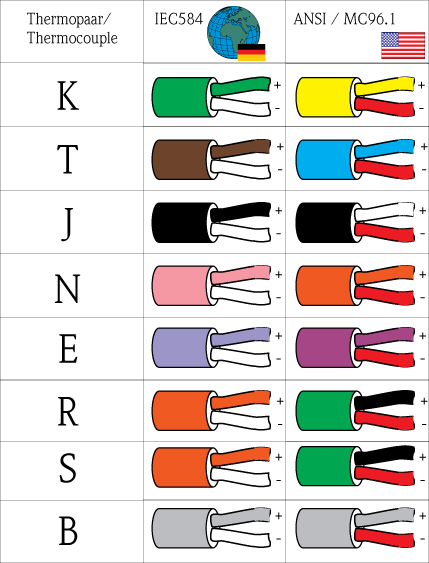

Thermo- and compensation cables are used in order to bridge the distance between the sensor (ceramic leg) and the electronics (transmitter) in the most economical manner. Thermocables are manufactured from the same material as the respective thermocouple. Compensation cables however are manufactured from special material that, in a limited temperature range, have the same thermoelectric properties as the respective thermocouple.

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

TC connection

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

There is an extension cable or a compensating cable for each type of thermocouple which reacts in a similar manner as the respective thermocouple (compatible) within a temperature range up to maximal 200 °C. Also the extension cables and a compensating cables are more economical and easier to install than the insulated thermocouple wires. The following table shows the mostly used insulation materials and their maximum temperature resistance for thermo- and compensation cables:

|

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||