|

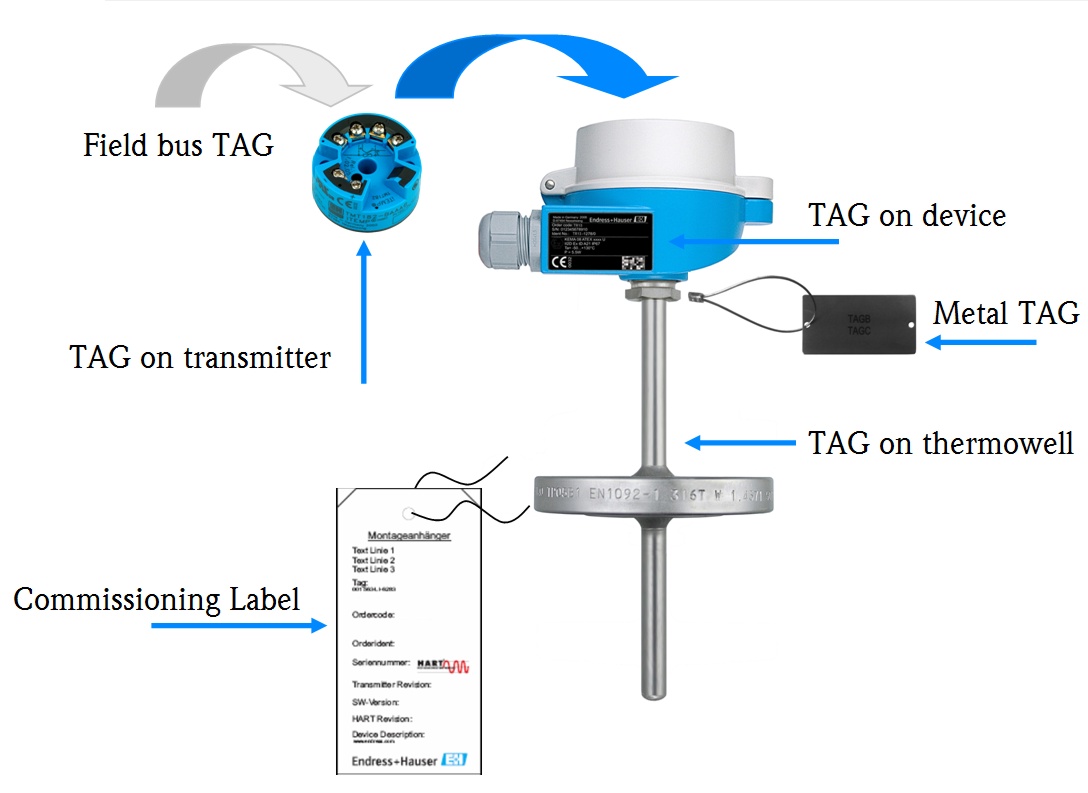

Field bus TAG

Field bus TAG marks the measurement point using the electrical interface. (PCP, HART, PA and FF).

On standardized field busses only those parameters that are defined by the respective norms are supported.

|

HART:

|

max. 8 characters

|

|

HART Descriptor:

|

max. 16 characters

|

|

Profibus:

|

max. 32 characters

|

|

Foundation Fieldbus

|

max. 32 characters

|

The Field bus TAG can be modified subsequently

by the customer using the set-up.

Metal TAG

The metal TAG can be removed and transferred to a replacement device. It can be fastened to

parts of the plant itself. The metal TAG is shipped

together with an attachment wire.

TAG on device

This TAG is permanently attached to the device either as a foil or lasered

or engraved.

Customer TAG

Customers can also issue an own tag plate or stick-on label and provide it with the order. The TAG number must already be engraved or

printed on the tag plate. These TAG plates then are shipped fastened to the device.

Commissioning Label

The TAG number is printed on a cardboard label. The label

is shipped fastened to the device. After installation

the commissioning label can be removed easily and is

exerted for the configuration of the instrument in the

control room.

|