Sensor class |

||||||||||||||

|

Pt100 temperature sensors for industrial temperature measurement are mainly produced in two basic forms. The so called thin flim sensors and the round ceramic sensors.

|

||||||||||||||

|

The Pt100 is fitted into a measurement insert. The measurement accuracy is dependent on various factors:

|

||||||||||||||

|

|

|

|

||||||||||||

| Pt100 temperature sensors | ||||||||||||||

|

Pt100: thin film Advantages: |

|

|

||||||||||||

|

|

|

|

||||||||||||

|

Ceramic Pt100 Advantages: |

|

|

||||||||||||

|

|

|

|

||||||||||||

|

Measurement accuracy sensor |

||||||||||||||

|

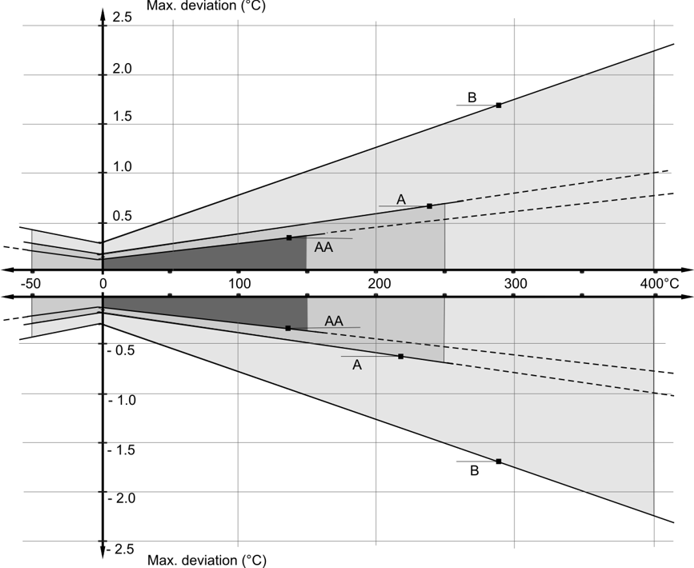

Tolerance classes: For Pt100 resistance thermometers two accuracy classifications are laid down in the IEC 60751:

Above these there are also higher accuracy classifications for special applications:

Note |

||||||||||||||

|

|

||||||||||||||

|

Measurement accuracy for Pt 100 thin film TF:

1) |t| = absolute value of the temperature in C° |

|

|

||||||||||||

|

|

||||||||||||||

|

Measurement accuracy for Pt 100 wire wound WW:

1) |t| = absolute value of the temperature in C° |

||||||||||||||

|

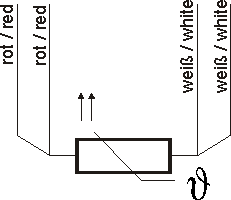

Connection modes |

||||||||||||||

|

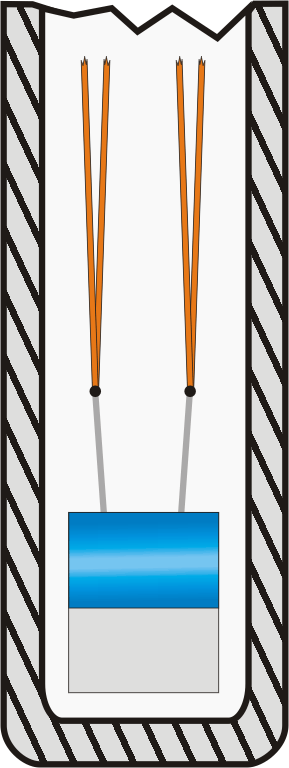

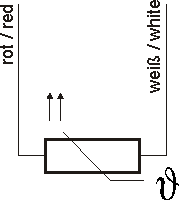

2-wire: |

|

|||||||||||||

|

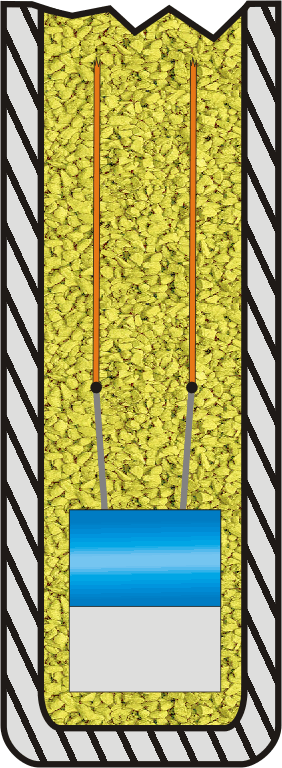

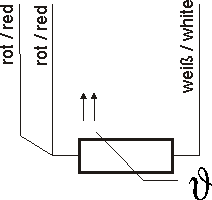

3-wire: |

|

|||||||||||||

|

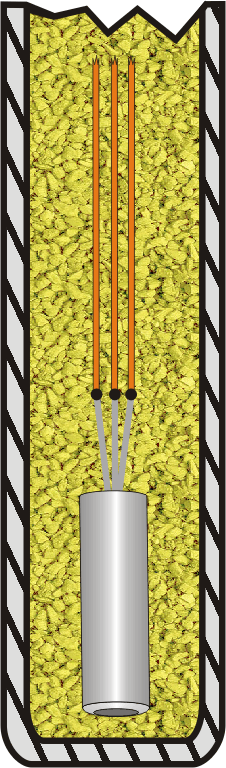

4-wire: |

|

|||||||||||||

Temperature inserts of Endress+Hauser by comparison

|

Sensor type |

Construction |

Application temperature range |

Dual sensor |

Best accuracy that is available for order by default |

Long term stability |

Best possible response time4) |

Vibration resistance5) |

|

|

RTD thin film (TF) |

|

-50 °C to +400 °C |

yes, on request |

Class AA (formerly

1/3 DIN B) according to |

++ |

+ |

+ |

+ |

|

RTD thin film (TF) |

|

-50 °C to +200 °C |

no |

Class A according to IEC 607512) |

+ |

+ |

++ |

+ |

|

RTD wire wound |

|

-200 °C to +600 °C |

yes |

Class AA (formerly 1/3 DIN B) according to |

++ |

+ |

+ |

0 |

|

Thermocouples (TC) |

|

-200 °C to +1800 °C |

yes |

Example for type K: |

0 |

0 |

++ |

++ |

|

|||||||||||||||||||||||||